Lean Roundtable

“Lean” Fu Panda

Yesterday is history, Tomorrow is a mystery, Today is a gift, that’s why it’s called a present.

Root Cause Analysis

Root Cause Analysis is an iterative problem solving technique used to identify causes of problems within organizations. RCA involves systematically identifying potential sources of issues and eliminating each until the issue disappears. Root cause analysis is commonly performed during quality audits and project management meetings.

In Lean Product Development, the concept of “Root Causes” is applied at different levels of the organization. At the lowest level, there’s the “Cause Why”. This is usually done through brainstorming sessions that involve everyone involved in the project. These sessions help uncover hidden assumptions about the customer, market, technology, competition, etc., which lead to decisions being made

Related Posts

How to Build Trust as a Modern Rep Using AI to Prep Smarter Conversations – Episode 136

Part 2 with Tom Walker on how modern manufacturers reps use AI to build trust, strengthen culture, and stay relevant in a changing sales environment.

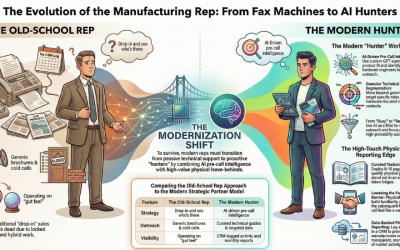

The Rep With a Fax Machine Is Losing

How manufacturing reps are using AI, smarter targeting, and disciplined workflows to win access, identify the right engineers, and support principals more effectively. Episode 135 with Tom Walker on modernizing the rep role.